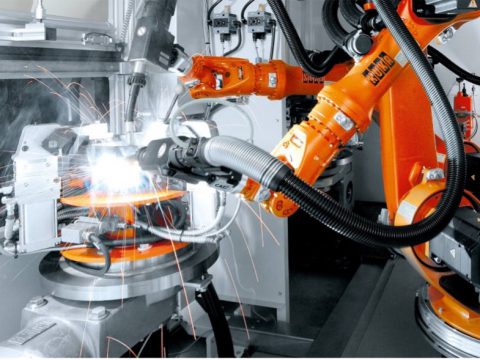

KUKA AND WINDHAGER: REDEFINING WELDING IN BOILER PRODUCTION

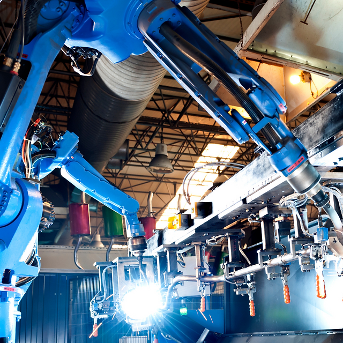

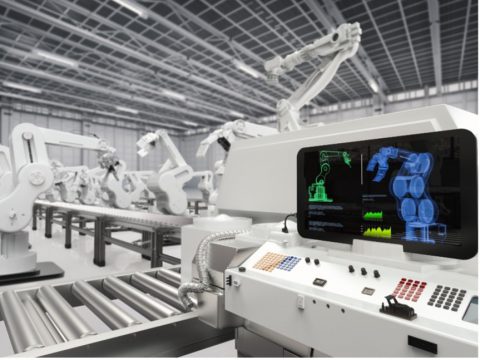

In the boiler manufacturing industry, precision and efficiency are vital to ensure high quality and durable products. KUKA, a pioneer in robotic automation solutions, is transforming this sector with its advanced automated welding line. This article explores how KUKA’s innovations are redefining boiler production standards and the benefits they bring to the industry. Precision and