THE IMPACT OF INDUSTRIAL ROBOTICS ON THREE-DIMENSIONAL SCULPTURE

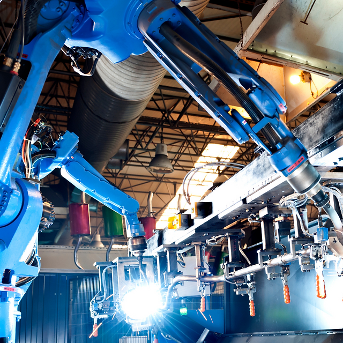

In the last few decades, the intersection between industrial robotics and art has generated an exciting field of creative exploration. Particularly, the application of carving robots in three-dimensional sculpture has revolutionized the way sculptural artworks are conceived and created. In this article, we will explore the impact of industrial robotics on sculpture, highlighting how technological