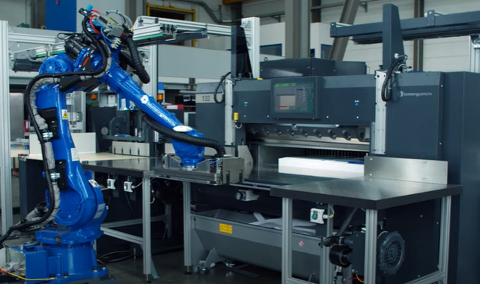

SCARA ROBOT THAT WITHSTANDS CLEANING PROCEDURES: A BREAKTHROUGH IN INDUSTRIAL ROBOTICS

In the field of industrial automation, SCARA robots (Selective Compliance Assembly Robot Arm) have been an effective solution for tasks requiring precision and repeatability. However, applications in industries demanding strict hygiene conditions, such as food, pharmaceutical, and optical industries, require greater resistance and the ability to withstand rigorous cleaning procedures. This is where the SCARA