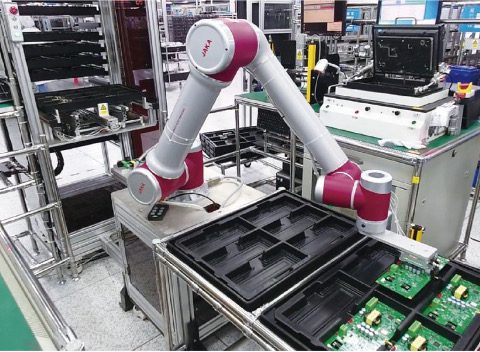

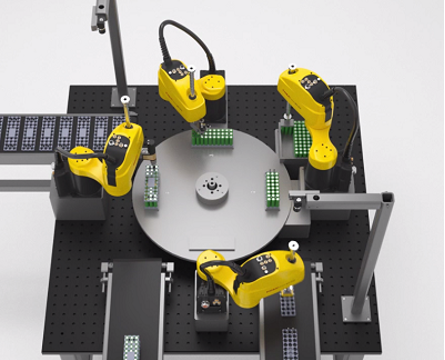

DOBOT AND JAKA: DEMOCRATIZING INDUSTRIAL ROBOTICS WITH EDUCATIONAL AND COLLABORATIVE ROBOTS

In recent years, the world of industrial robotics has witnessed a significant change, marked by the democratization of access to this innovative technology. Companies like Dobot and JAKA have played a crucial role in this process, developing educational and collaborative robots that are revolutionizing the way robotics is taught, learned, and applied in various environments.