HOW DO LEADING INDUSTRIAL ROBOTICS COMPANIES OFFER INNOVATIVE AND EFFICIENT SOLUTIONS TO IMPROVE PRODUCTIVITY, QUALITY AND SAFETY IN DIFFERENT INDUSTRIES, SUCH AS PACKAGING, LOGISTICS AND PICK AND PLACE?

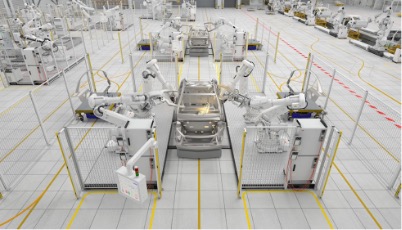

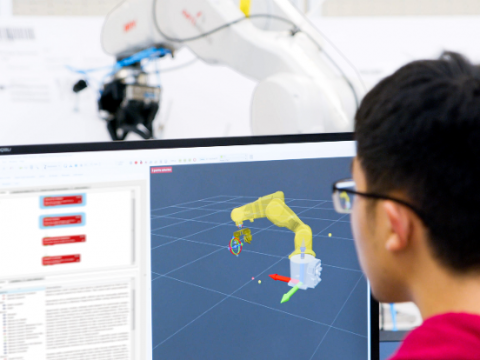

Automated robotics offers the possibility to improve the performance, quality, and adaptability of production processes in different sectors. By using intelligent robots, human error can be reduced, the use of resources can be optimised, and products can be customised according to customer needs. It improves sustainability, reduces environmental impact, and increases quality. Builders can anticipate