DEPALLETISING AND PALLETISING ROBOT SYSTEMS FOR LOGISTICS AUTOMATION WITH ROBOTS FROM UNIVERSAL ROBOTS

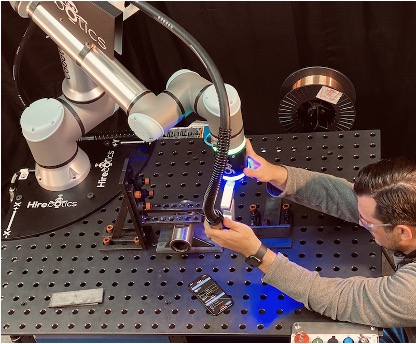

Logistics centres don’t send pallets of single items, but shipments of mixed items. Huge trucks deliver items to the logistics centre and someone must unload the truck. During the unloading of the truck, each item must be registered and then stored. For this purpose Universal Robots and Mujin Corp created an automated system. With the