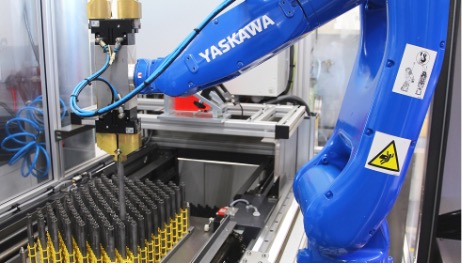

THE YASKAWA MOTOMAN GP20 ROBOT: AN EXAMPLE OF INNOVATION AND PRECISION IN AUTOMATION

The Yaskawa Motoman GP20 robot is a 6-axis robot that has a payload of 20 kg and a reach of 1,802 mm12. It is a compact, high-speed robot that can achieve very fast cycle times with excellent repeatability. The slim design of your wrist allows you to work in tight spaces and access difficult areas,