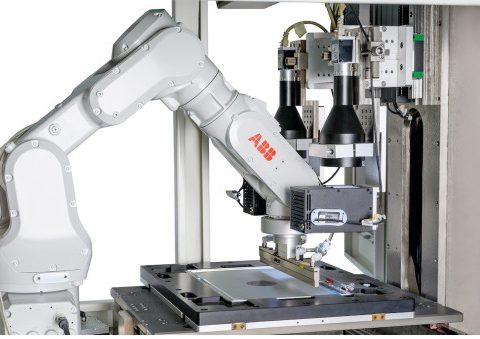

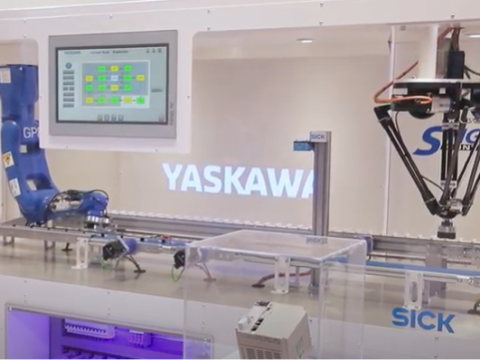

VISION AND FORCE CONTROL TECHNOLOGIES, FANUC

Industrial robots are constantly being upgraded and improved as technology advances tremendously as we move forward in the automation industry. Force sensing and robot vision are combined in industrial robots to generate haptic intelligence. These procedures are continually being improved by manufacturers, who also manage to raise production quality while reducing prices. FANUC force sensors