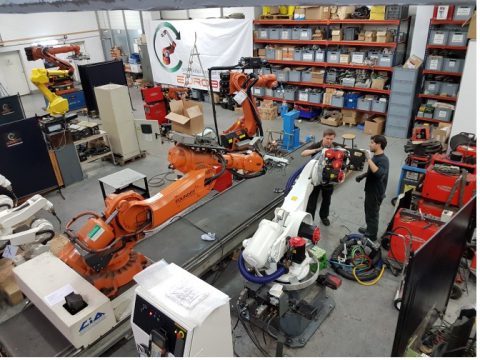

ROBOT PROGRAMMING

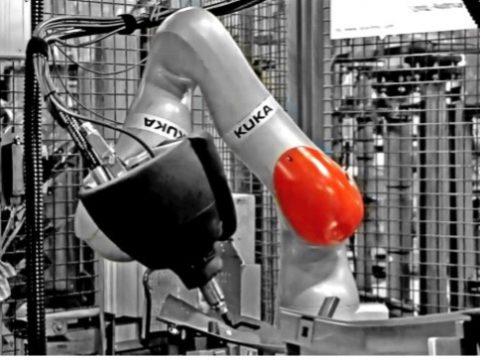

The vast majority of jobs still require manual programming, although new offline robot programming tools are evolving and becoming more widely used. The industry standard for CNC machine programming is to employ robust, easy-to-use offline software. As a result, overall manufacturing costs have been reduced, accuracy has improved, machine downtime has been reduced, more complex