Robots can be traced as far as the Renaissance era, where Leonardo Da Vinci started utilizing mechanical devices in his work. However, the use of robotics in the automotive industry is relatively new; it took some time for robots to evolve and contribute in car manufacturing.

We’ll be exploring the history of robotics in the automotive industry to understand how robots came to where they are now.

Rise of Automotive Industry After WWII

After the fall of the Third Reich, the world entered a new age and experienced a leap in technology. The demand for cars was more than ever as the economy recovered and people had higher purchasing power.

It soon became apparent that the current methods of car manufacturing will not be enough to meet the demands; faster and more efficient ways of manufacturing are needed. This is the time when the idea of automation started to float around.

But it wasn’t until 1970 when the first integrated circuit was invented. The robots did not have any sort of external sensors back then; however, they were able to perform some basic functions in the overall manufacturing process.

Industrial Automation

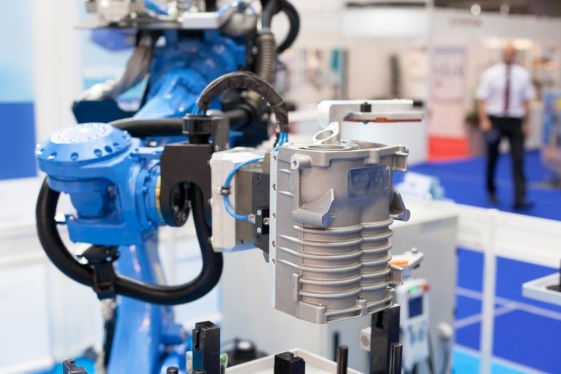

General Motors was the first company to develop a robot for welding in their manufacturing plant. Their method was soon adopted by Ford, and it quickly became a widely used method by other manufacturers.

The famous Stanford Arm was invented in 1969, which allowed a greater variety of movement, thus laying the foundation of extensive use of robotics in the industry.

1974 saw the invention of the revolutionary Silver Arm. Developed by MIT, the arm had a microprocessor and multiple sensors which gave it the ability to sense pressure.

The 1980s can be considered as the automation boom in the automotive industry, as companies started to heavily invest in automation for their assembly lines. This changed car manufacturing for good.

Automotive Robotics Today

The US automotive industry saw a boom in 2010 and experienced an increase in manufacturing. The US is also third when it comes to robot density (robot per 1,000 employees), outranked by only Japan and Korea.

China is largest consumer of industrial robots today, as well as the largest manufacturer. It installed 108,000 industrial robots in the period between 2011 and 2016. The great thing about industrial robots today is that they have become quite inexpensive and easily accessible to even small manufacturers.

Many manufacturers also have the option of buying used robots, which are in a pretty good condition and are sold at reasonable prices.

The Future of Automation

The use of robotics in the automotive industry is only expected to rise, as technology is making constant progress.

However, with increased emphasizes on waste management and environmental sustainability, we could see better manufacturing processes gauged by more efficient robots.

We are one of the leading used robots’ traders and deal with all sorts of industrial robots. Visit our website to learn more.