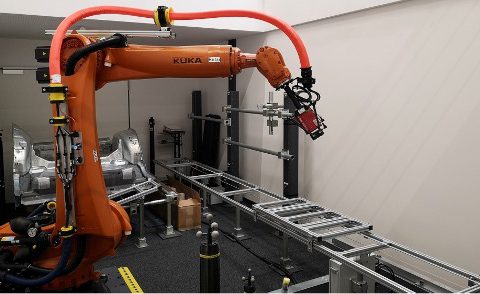

WHAT ARE THE IMPROVEMENTS WITH THE INTRODUCTION OF AI IN INDUSTRIAL ROBOTICS

In recent years, artificial intelligence (AI) has revolutionized many aspects of our lives, including the robotics industry. With the integration of AI into industrial robots, significant improvements have been achieved in terms of efficiency, precision and adaptability. In this article, we will explore some of the major improvements that have come with the introduction of