SAFETY ADVANCES FOR COLLABORATIVE WELDING: A PROTECTED FUTURE

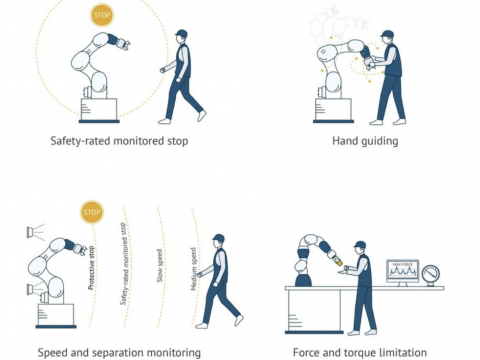

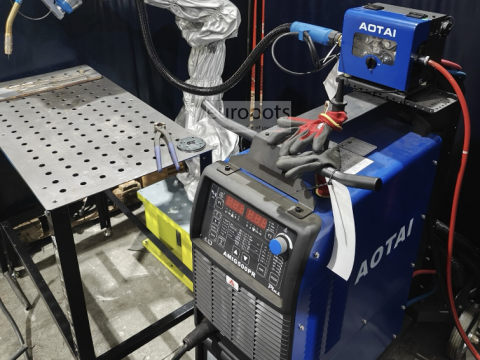

The welding industry, long associated with high-risk environments, is undergoing a profound transformation thanks to the rise of collaborative robotics. In modern welding facilities, safety is no longer just about regulatory compliance—it has become a cornerstone of operational efficiency and worker well-being. At the heart of this shift lies the strategic deployment of collaborative robots,