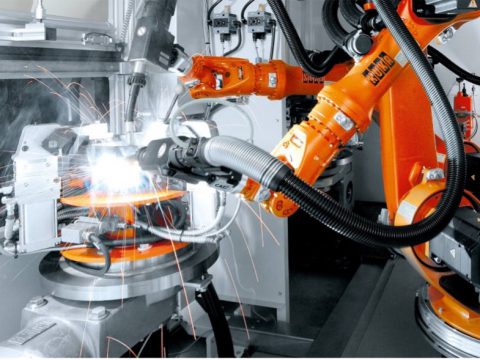

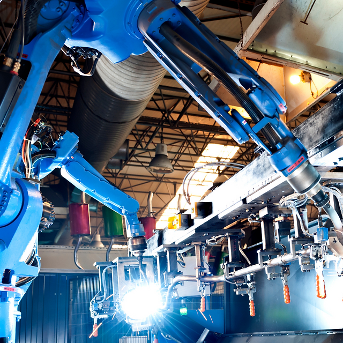

THE DOBOT CR10 COBOT MIG MAG SOLUTION FROM EUROBOTS AND AOTAI

In a world where precision and efficiency are the backbone of the manufacturing industry, automation has become the key to staying competitive. UsedRobotsTrade (URT), a leader in robotic solutions has raised industry standards with its innovative welding solution: the DOBOT CR10 COBOT MIG MAG COBOT in collaboration with AOTAI. Innovation in Collaborative Welding The DOBOT