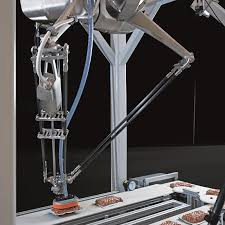

The new robot from the FANUC DR-3iB/8L series is based on the classic parallel link design. A new generation of delta robots has been specifically designed to maximize speed and versatility in sorting and packaging applications, in operational areas in the food line.

New Design Features

The DR-3iB/8L has a payload of 8 kg, a horizontal reach range of 1600 mm and a vertical reach range of 500 mm. Its size and coverage allow production line manufacturers to easily integrate this delta robot into pick and place applications of various sizes.

New design features make programming, cleaning, and sanitizing easier, while meeting even the most stringent food safety requirements.

Advanced movement performance, up to a movement speed of 10,000 mm/s, makes the DR-3iB/8L an ideal choice for typical pick-and-place and packaging applications in the food and beverage industry.

It provides greater payload, inertia and the longest reach, making it a feasible solution for a variety of processes.

Benefits of FANUC DR-3iB/8L

This new system of automation solutions complies with the indicated settings to make good use of space. While testing the DR-3iB/8L, easy installation, operation and maintenance were observed. The hollow wrist design (Ø = 20mm) fixes the wiring harness neatly inside the robot, which can help prevent mechanical interference and facilitate a clean installation.

DR-3iB/8L is surface coated with electroless nickel plating. It has no springs, no stickers, or pocket closures, and its sloping surface allows it to self-drain, encouraging non-maintenance. This self-draining feature makes it suitable for integration into the food sector.

The auxiliary collection box and observation window on all main shaft reducers allow the user to pre-check for grease leaks, before anything comes out of the robot.

Improved Functionality

The installation structure is convenient for cleaning the vacuum hose and cable wiring along the robot arm. It features a 20mm hollow wrist, which can be easily connected to the EOAT. These functions can better control the cable and extend its life.

The IP69K protection rating of the DR-3iB/8L makes it suitable for environments with strict washing standards. Its payload capacity allows the handling of heavier products at higher transport speeds. Additionally, its additional brake release switch allows users to move the robot comfortably without programming the console.

Last but not the least, it works with software that allows several robots on the same line to efficiently operate at high speeds, since it incorporates iRVision and the FANUC iRPickTool conveyor tracking software.

About UsedRobotsTrade

A company specializing in the refurbishment and sale of used robots, UsedRobotsTrade has a variety of robots on sale. They deal not only in industrial robot parts, but also in Mitsubishi robots, ABB spare parts, robotic welding systems and more.

Contact them to buy robotic parts that are the right fit for every project.