Automating the welding application required development and optimization in the industry. By integrating industrial robots into the process, reducing downtime and thus increasing productivity became possible.

Meet the Companies

Chaigneau Frères Tôlerie Fine Industrielle is an ISO 9001 and ISO 14001 certified French company dedicated to the manufacture of parts for construction, agricultural, and machinery industries, among others. It has extensive experience in boiler-making, mechanical welding, cutting and powder coating.

It was hoped that Yaskawa Motoman Corporation, one of the world’s leading manufacturers in the fields of drive technology, industrial automation and robotics, would be able to provide a solution for increasing production and improvement in series welding.

Goals of The Project

The purpose of the project was to introduce welders to a new approach for producing more technical parts with greater added value, and in the same way, producing smaller batches.

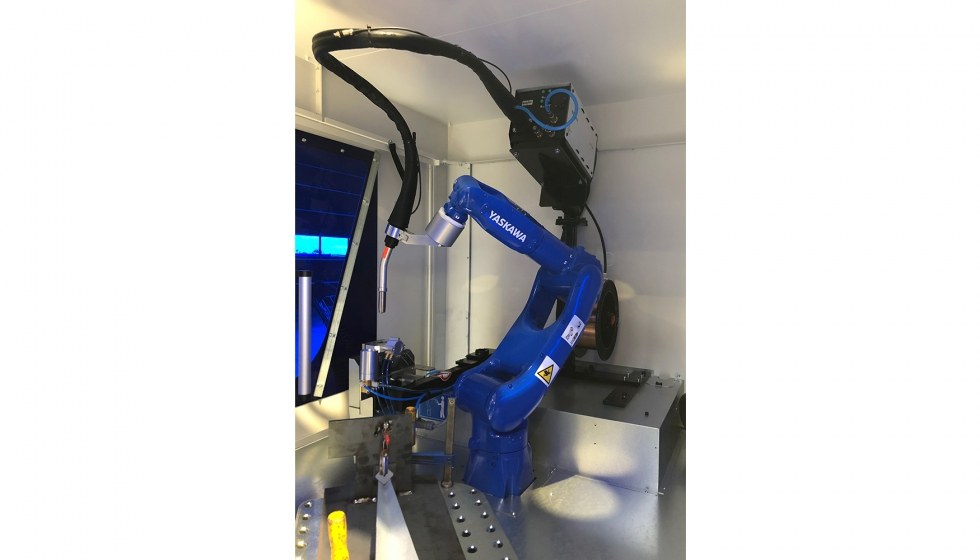

Meeting the requirements and expectations of the company, Yaskawa proposed the “turnkey” solution for the ArcWorld RS Mini unit, which was ultra-compact and easy to install.

Various Advantages

The ArcWorld Mini system was designed to provide flexible, cost-effective and space-efficient options.

The robot cell is completely covered and manufactured on a platform that facilitates its movement and incorporation of robotic technology in the welding application. This leads to an increase in production while reducing the required time.

One of the main advantages is its ease of installation, programming and use.

Efficient Design

The system is designed to get started quickly and increase productivity in a small area, and the investment cost is low. If, at any time, the production process needs to be changed, the robot workstation can be easily relocated to another area of the factory.

Marc Brilland, production manager said, “The compactness and ease of installation of the battery allowed us to start production quickly and efficiently. After a year of use, this investment has met expectations.”

It is an ‘all-in-one’ solution. It is the ideal option to replace or complement manual welding at will, allowing the reduction of downtime, thereby increasing productivity. The flexibility of this system can provide better profitability, greater stability and an increased competitive edge.

About UsedRobotsTrade

A company specializing in the refurbishment and sale of used robots, UsedRobotsTrade has a variety of robots on sale. They deal not only in industrial robot parts, but also in Mitsubishi robots, ABB spare parts, robotic welding systems and more.

Contact them to buy robotic parts that are the right fit for every project.