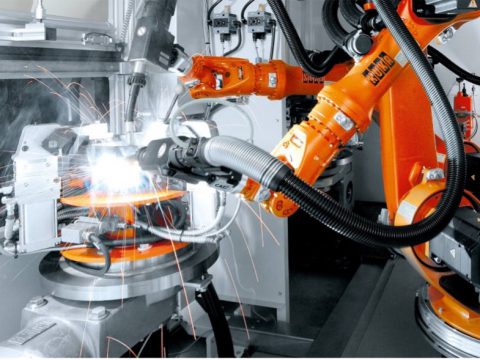

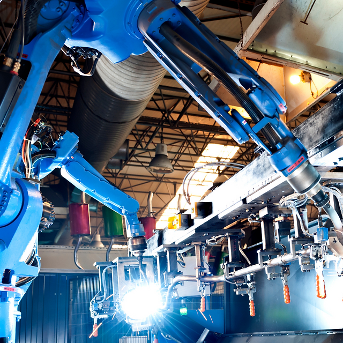

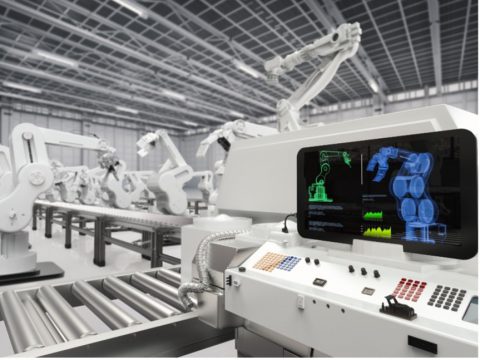

YASKAWA DRIVES EFFICIENCY: NEW ROBOTIC SOLUTIONS FOR WELDING, MATERIAL HANDLING AND CONTAINER PICKING

At the recent robotics event in Chicago, Yaskawa Motoman dazzled the industry with an impressive display of its latest robotic solutions. The company, known for its leadership in industrial automation, showcased a range of robots designed for welding, material handling and container picking applications, once again demonstrating its commitment to innovation and efficiency. High Precision