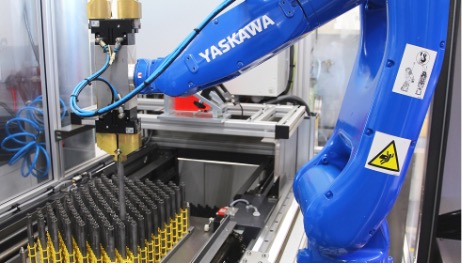

INDUSTRIAL ROBOTS IN ROBOTIC MILLING AND CUTTING

Industrial robots are automated machines that can perform various tasks in industry, such as milling, cutting, welding, painting, among others. In this article, we will focus on robots used in robotic milling and cutting. ROBOTIC MILLING Milling is a machining process that involves removing material from a part with a rotating tool called a milling