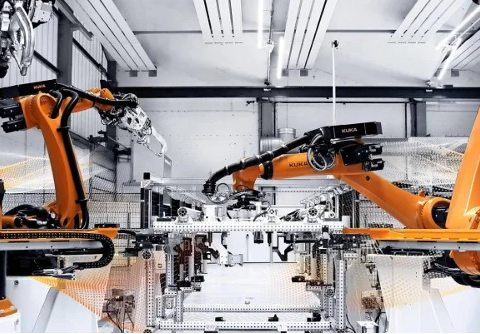

YASKAWA LAUNCHES MOTOPICK 4 SOFTWARE TO BUILD PALLETS QUICKLY AND EFFICIENTLY WITH ROBOTS

Yaskawa, one of the leading companies in the industrial robotics sector, has unveiled its new Motopick 4 software, which makes creating and optimising robot palletising patterns simple and accurate. The software is compatible with the YRC1000 and YRC1000micro robot controllers, which are the most advanced and compact in Yaskawa’s range. The software offers an intuitive