UNIVERSAL ROBOTS TAKE PRECISION TO THE NEXT LEVEL IN PAINTING WITH UR10

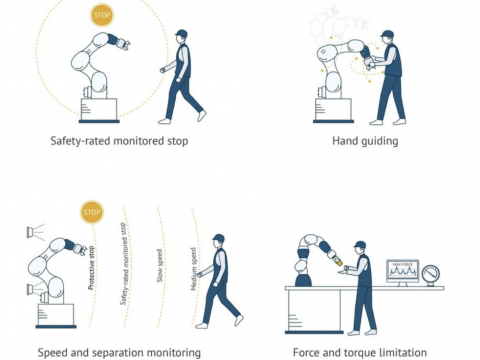

Collaborative robots like the UR10 are reshaping industrial painting in remarkable ways. One standout example is Brandt A/S, a Danish company with over 60 years of experience. In October 2024, the International Federation of Robotics (IFR) released a study highlighting how integrating UR10 cobots in finishing operations has enhanced precision, consistency, and efficiency across the