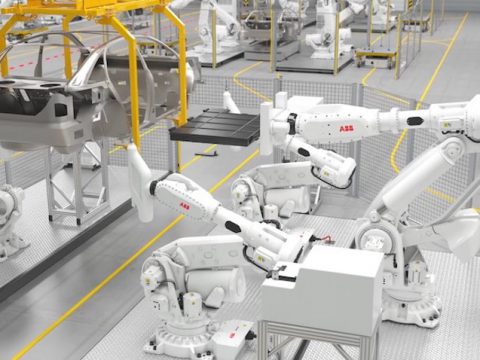

INDUSTRIAL ROBOTS VS. TRADITIONAL PALLETIZING SYSTEMS

Palletizing is one of the most critical stages at the end of the production line. Although it is often perceived as a simple process, in practice it involves occupational risks, production bottlenecks, and hidden operational costs. For many years this process has been handled using traditional systems: manual palletizing, semi‑automatic solutions, or low‑flexibility dedicated machines.