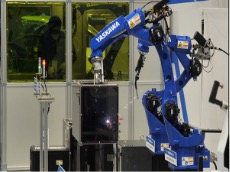

FACTORS TO CONSIDER WITH YASKAWA PAINTING ROBOTS

Paint robots fine-tune the spraying of paint or adhesives, bringing clear benefits. The long-term use of robotic automation helps industries save on materials and costs by establishing a safer working environment and delivering consistent end quality. A slim-arm, compact robot design with high speed and six axes is perfect for a successful paint application. Product